ACTIVITIES

|

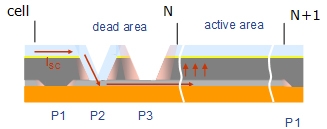

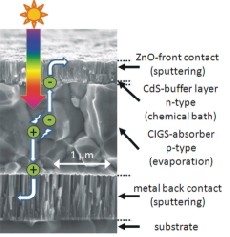

CIGS scribing cluster: Assessment of new equipment & reliable laser scribing processes Assessment of equipment and its interaction â–ª new wavelengths from ps-laser; â–ª ps-fiber laser with pulse on demand feature; â–ª fast polygon scanner; â–ª on-line scribing process monitoring tool; Integration & assessment in the process Final validation at end-user facilities Approaches for thin-film CIGS solar cells on different substrates (glass, polymer, metal)

|

Standard monolithic integrated interconnect scheme: P1, P2 and P3 scribes have been performed between deposition steps Key issues: â–ª selectivity in layer processing; â–ª narrow “dead” interconnection zone; â–ª minimised residual side effects; â–ª high process speed. |

|

|

|

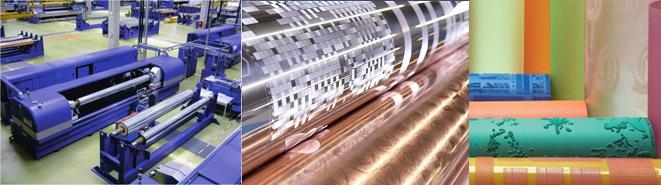

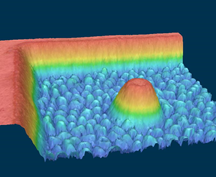

Texture cluster 1: Fast structuring for printing & decoration High resolution 3D micro-structuring with ultra-short pulse lasers for embossing: â–ª evaluation and validation of the lasers and fast scanning polygon devices; â–ª integration of the fast scanning devices on an existing gravure setup; â–ª evaluation of process strategies and process parameters for industrial production; â–ª validation of equipment in development of special structures for decoration. |

|

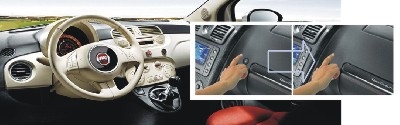

Texture cluster 2: Surface functionalisation Surface engineering – to create soft-touch and anti-glare effects by functional textures on molds for automotive industry â–ª Assessment and optimization for 3D mold texturing method; â–ª Validation of combined technology by production of real automotive part with added soft-touch texture.

|

|

|

|

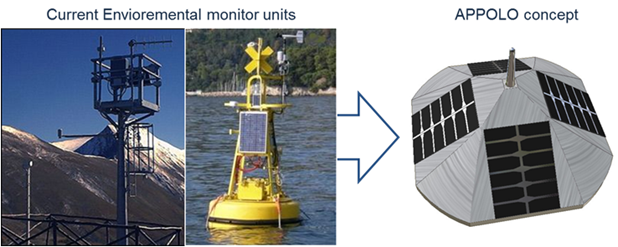

Laser Direct Writing cluster 1: 3D interconnections on plastics Validate reliable schemes for direct writing of 3D wiring by laser radiation: â–ª overcome basic problems of current state of the art; â–ª process standard plastics instead of using highly specialized costly material; â–ª saving resources by adding material for laser functionalisation. Demonstration of new capabilities in surface functionalisation by lasers for 3D wiring and flexible electronics; Assessment of new laser beams for writing 3D / flexible electronics; Validation of the electric interconnections made by lasers in real conditions: automotive & environmental sensing.

|

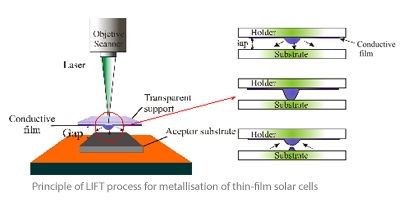

Laser Direct Writing cluster 2: LIFT for Photovoltaic Applications The laser-induced forward transfer (LIFT) process is a local technique to transfer different materials. LIFT uses laser pulses to push thin disks of a ribbon material from a transparent substrate and deposit them onto an acceptor substrate. Laser direct writing of flex electronics and photovoltaics in planar geometry will be assessed and validated: â–ª adding material techniques (especially LIFT): â–ª post-deposit firing/curing techniques using laser technology. Particular goals are: â–ª demonstration of new capabilities in surface functionalisation by lasers for flexible electronics and photovoltaics; â–ª assessment of new laser beams (wavelength, etc.) for writing and metallization in flexible electronic including material deposition (LIFT) and laser curing/firing. â–ª apply to define in a single step the fingers of front contact in a photovoltaics device. |

|

|

|

On-line monitoring tools Development and validation of on-line monitoring tools and beam control systems which are necessary: â–ª process control during the assessment experiments; â–ª on-line tools to be assessed and integrated into laser processing systems. On-line tools for integration into laser processing systems: â–ª surface profile monitoring tool with polygon scanner; â–ª auto-focusing unit for laser processing in 3D electronics.

|

New equipment assessment experiments selected after Open call procedure:

|

FAST: Breakthrough solutions in laser patterning for reduced friction

|

|

PONT: Breakthrough solutions in resonance NIR laser texturing of polymers

|

|

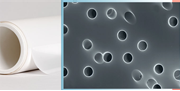

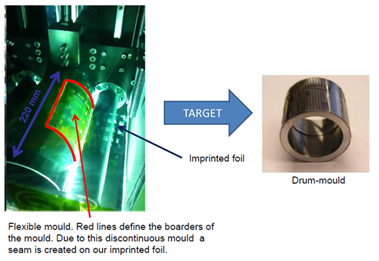

LADRUM: Breakthrough solutions in laser patterning of drum-moulds for large-area nano-imprinted polymer films

|

|

NEW-DELI: Breakthrough solutions in fibre-based delivery system for pulsed laser beams

|

|

|

FastGALVO: Breakthrough solutions in ultra-fast galvoscanners for laser micromachining

|

|

.png) |

DECOUL-Cr: Breakthrough solutions in ultrafast laser equipment for decorative finishing in automotive chrome plated parts

|

|

SUN-JELL: Breakthrough solutions in laser marking for jewellery

|

© Copyright APPOLO. All Rights Reserved / internal website / Website solution: @KIM